Affordable computer vision wood scanner, sorting, grading and cut optimization of sawn timber, gluelam manufacturing process upgrade.

info@knotinspector.com

Setup

KnotInspector computer appliance may have different configurations depending on the conditions at the production line. We are ready to design an individual configuration to minimize the need for modification of your production line.

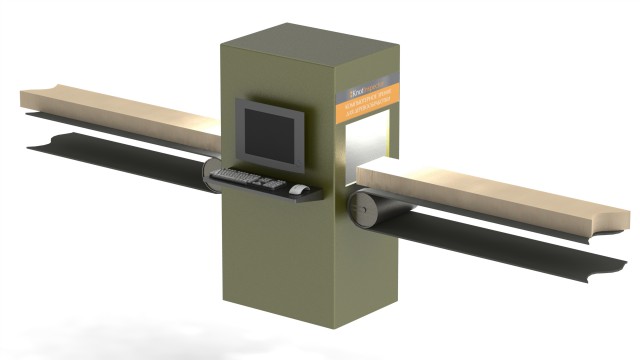

KnotInspector components

KnotInspector consists of the following components:

- Image capturing unit, comprising:

- video cameras,

- LED backlighting,

- encoder.

The number of cameras and lamps depends on how the lumber needs to be examined (the number of sides to be examined) and the geometry of the image capturing unit (the installation opportunities of the existing line). The number of cameras may vary from 1 to 4. The distance between the image capturing unit and the unit which reads the marks should be not less than the length of lumber.

- Image processing unit includes special-purpose software and computer hardware designed for fast image processing.

- The cross-cut saw interface unit transmits signals to the saw as if it read the marks made with fluorescent chalk.

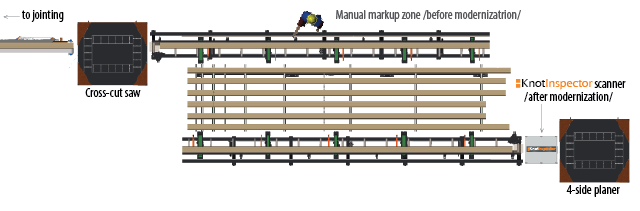

Modernization of production line

Image capturing equipment is installed on the lumber supply line and the computer which decides how to cut the material is connected to the controller of the cross-cut saw instead of sensors that read the position of marks made with fluorescent chalk. However, the unit for reading the marks can remain to make it possible to switch back to manual marking if necessary. So the functionality of the crosscutting line remains the same but manual marking using fluorescent chalk is no longer needed.

Prototyping

Stopping the production line for modernization is often a sensitive issue for the company, because each day of downtime is a waste of money. We reduce downtime to a minimum, using prototyping and checking scanner design at your enterprise before making its industrial version.

To choose the optimal configuration, we make a spatial prototype of the image capturing unit and test the operation of the software system on it. It makes it possible to add the industrial version of the scanner to the geometry of the line on the first try.

Maintenance

Computer vision system has no moving parts and does not require frequent maintenance. However, there are two requirements which must be met for successful operation of the solution on the customer side:

- An employee involved in implementation and trained to set up and calibrate the optical part of the appliance.

- Remote Internet access to the appliance processing unit to update the software and perform troubleshooting if there are any troubles without visiting the customer.

Whatever your tasks may be, we will help you to solve them with KnotInspector.

Find out about KnotInspector prices and pre-order conditions >>