Affordable computer vision wood scanner, sorting, grading and cut optimization of sawn timber, gluelam manufacturing process upgrade.

info@knotinspector.com

Technology

Computer vision cameras and LED backlighting ensure that the system receives an accurate image of each incoming board. Obtained data is used to determine precise dimensions of the board and to search for defects in wood.

The information on the exact location, type and size of defects of the board resulting from image analysis is used for optimal cutting of the board according to the current task.

Board cutting data is transmitted to the controller of the cut-saw which cuts out the defective areas and, if required, to the pushers which sort the lumber received after crosscutting by grade classes.

Image capture equipment is installed on the lumber supply line and the computer which decides how to cut the material is connected to the controller of the cross-cut saw instead of sensors that read the position of marks made with fluorescent chalk. However, the unit for reading the marks can remain to make it possible to switch back to manual marking if necessary. So the functionality of the crosscutting line remains the same but manual marking using fluorescent chalk is no longer needed.

Wood species

KnotInspector scanner can be adapted to work with any wood species. However, only the pine is included in the standard delivery. Libraries for other species of wood are prepared based on pre-orders received and can be installed and updated on the scanner at any time after its introduction.

Please contact us and tell us what species of wood you would like to use the scanner for.

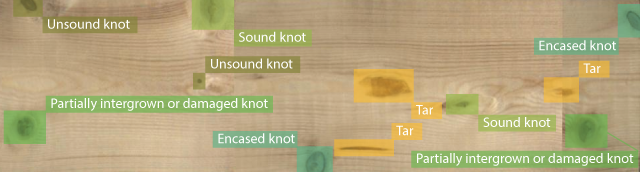

Classification of wood defects

Classification of wood defects is based on standard ISO 2299:1973, «Sawn timber of broadleaved species — Defects — Classification». We have created a concise yet effective classification which can be used to create a variety of specifications corresponding to different grades of lumber.

Knots

- Sound knot

- Partially intergrown or damaged knot

- Encased knot

- Unsound knot

Other visible defects

- Krack

- Stain

- Tar

- Darkening

- Waine

- Pith

- Mechanical damage

Determined parameters of defects

- Size and position on the board is determined for all defects.

- Degree of discoloration is determined both by the area and by strength.

Cut optimization and sorting parameters

Precise determination of wood defects, their type and location, allows you to customize the system to meet any specifications, including different specifications for internal and external veneers of laminated veneer lumber. Speciality of specifications is developed individually for the task according to the documentation of the enterprise.

Find out more about KnotInspector installation on your production line >>